Print This Page

Print This Page Email This Page

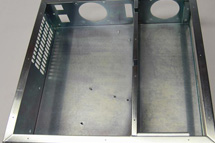

Email This PageFabrication of a Steel Chas Detector Rackmount

(click on thumbnail to enlarge)

At Middleton Machining, our turnkey steel fabrication services provide our customers with a one-stop solution for their fabrication projects. Instead of having to collect quotes and place orders with multiple manufacturers, we offer a streamlined solution to customers with sheet metal fabrication, machining, plating, painting, and printing needs. This turnkey project is a fabricated steel chas detector rackmount produced for our customer in the laboratory equipment industry.

The rackmount measures 27.456" x 28.603" flat and 17.13" x 15.98" x 5.16" after assembly. It is fabricated from hot rolled oiled and pickled steel using our saw, punch press, press brake, Pemserter, drill press, Timesaver, and TIG welding equipment. Even with its size and the amount of welding that goes into the rackmount, our in-house fixturing allows us to hold dimensional tolerances of ±.005". After fabrication, the rackmount is zinc plated and printed using silk screening per the customer's specifications. All assemblies undergo dimensional and visual inspection before shipment to ensure all of our customer's specifications are met. For more information about this steel chas detector rackmount, see the table below, or contact us directly.

Highlights of this Steel Chas Detector Rackmount Project

- Product Description

- Laboratory equipment in the scientific field

- Steel Fabrication Capabilities Applied/Processes

-

- Primary:

Fabrication- Punch Pressing

- Shearing

- Drilling

- Press Brake

- Grinding

- Welding - TIG

- Secondary:

Assembly

Silk Screening

Zinc Plating

- Primary:

- Equipment Used to Manufacture Part

- Saw, Punch Press, Shear, Press Brake, Pemserters, Drill Press, Welder, Timesaver

- Overall Part Dimensions

-

- Length: 17.13"

Width: 15.98"

Height: 5.16" - Length (Flat): 27.456"

Width (Flat): 28.603"

- Length: 17.13"

- Tightest Tolerances

- ±.005"

- Material Used

- Hot Roll Pickled and Oiled Steel

- Material Finish

- Zinc Plated

- In process testing/inspection performed

- Dimensional Inspection, Visual Inspection

- Industry for Use

- Scientific instruments

- Volume

- 24

- Delivery/Turnaround Time

- 6 weeks

- Delivery Location

- Madison, Wisconsin

- Standards Met

- Customer Specifications, 2D CAD Drawing

- Product Name

- Chas Detector Rackmount